Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

Top 2025 Trends in PCB Manufacturing and Assembly You Need to Know

The PCB manufacturing and assembly industry is poised for significant transformations in the coming years, driven by rapid technological advancements and evolving market demands. As businesses and consumers increasingly rely on electronic devices, the need for efficient, reliable, and high-quality printed circuit boards (PCBs) has never been more critical. This introduction to the top trends shaping PCB manufacturing and assembly for 2025 will provide insights into the innovations that are redefining the landscape.

From the adoption of advanced materials and automation technologies to the integration of artificial intelligence and sustainable practices, the future of PCB manufacturing and assembly is marked by exciting possibilities. Industry players are recognizing the importance of flexibility and responsiveness to stay competitive in a fast-paced environment. As we delve into these trends, it becomes evident that the PCB manufacturing and assembly sector is not only adapting to current needs but is also paving the way for a smarter, more interconnected future. Embracing these changes will be essential for companies aiming to thrive in the dynamic electronics market.

Table of Contents

[Hide]

Top Trends in PCB Manufacturing: Key Innovations for 2025

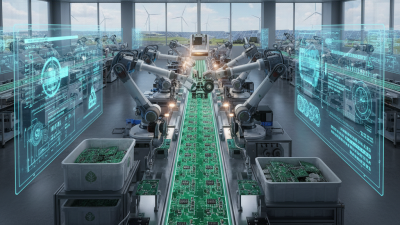

As we move towards 2025, the landscape of PCB manufacturing and assembly is rapidly evolving, driven by technological advancements and market demands. One of the key innovations is the increased adoption of automation and Industry 4.0 practices. According to a recent report from IPC, around 75% of PCB manufacturers are incorporating smart manufacturing solutions to enhance efficiency and reduce production costs. This shift allows for real-time monitoring and predictive maintenance, leading to improved product quality and shorter lead times.

Another significant trend is the push for sustainability within the industry. With rising awareness of environmental impacts, many manufacturers are exploring eco-friendly materials and processes. Research from the Electronics Industry Citizenship Coalition predicts that by 2025, at least 50% of PCB production will utilize sustainable materials, including recyclable substrates and lead-free solder options. This focus not only helps in meeting regulatory standards but also appeals to an increasingly environmentally conscious consumer base. As these innovations shape the future, manufacturers must adapt to remain competitive and meet the evolving expectations of both industries and consumers alike.

Top 2025 Trends in PCB Manufacturing and Assembly

Rising Use of Automation in PCB Assembly and Manufacturing Processes

The rising use of automation in PCB assembly and manufacturing processes is transforming the landscape of the electronics industry. According to a recent report from the IPC (Association Connecting Electronics Industries), the global PCB market is projected to grow at a CAGR of approximately 4.7% from 2023 to 2028, with automation playing a crucial role in increasing efficiency and reducing labor costs. Automation technologies, such as automated optical inspection (AOI) and pick-and-place machines, are streamlining production processes, enabling manufacturers to achieve higher quality control and faster turnaround times.

Moreover, as the industry shifts towards more complex designs and higher volumes, the integration of robotics and artificial intelligence (AI) becomes increasingly vital. A study from Deloitte indicates that companies employing automation have seen a productivity increase of up to 30%, allowing them to better meet the demands of a rapidly evolving market. By leveraging automated systems, manufacturers can enhance precision while minimizing the risks associated with human error, facilitating the assembly of intricate circuits that are becoming standard in today’s electronic devices. With automation at the forefront, the future of PCB manufacturing is set to be more efficient and less labor-intensive, paving the way for innovation and growth across the sector.

The Impact of 5G Technology on PCB Design and Production

The advent of 5G technology is revolutionizing various industries, and its impact on printed circuit board (PCB) design and production is particularly significant. As the demand for higher bandwidth and faster data transfer increases, PCB manufacturers are now tasked with developing more sophisticated designs that can support these requirements. This includes optimizing layer counts, reducing signal loss, and enhancing thermal management. 5G applications require PCBs that can operate at higher frequencies, leading to a need for materials with lower dielectric constants and advanced manufacturing techniques to ensure reliability and performance.

Moreover, the production process is evolving to meet the challenges posed by 5G technology. The use of automation and smart manufacturing approaches is becoming more prevalent in PCB assembly. Advanced techniques such as laser drilling and the integration of artificial intelligence for quality control are becoming critical. These innovations not only enhance production efficiency but also help in coping with the complexities of new PCB architectures necessitated by 5G applications. As 5G networks rollout globally, PCB manufacturers must adapt quickly to these trends, ensuring they remain competitive in a rapidly changing market landscape.

Sustainability in PCB Manufacturing: Eco-Friendly Materials and Practices

Sustainability has emerged as a critical focus in PCB manufacturing, reflecting the industry's response to growing environmental concerns. Eco-friendly materials and practices are not just trends; they are essential for reducing the ecological footprint of electronics production. Companies are increasingly seeking materials like biodegradable resins and recycled substrates, which not only minimize waste but also help in conserving natural resources.

Implementing sustainable practices in PCB assembly can significantly enhance a company's reputation and operational efficiency. For instance, adopting energy-efficient equipment and processes can reduce energy consumption and lower production costs. Moreover, using water-based or solvent-free inks can improve workplace safety and reduce harmful emissions.

Tips for Sustainable PCB Manufacturing:

1. Evaluate Material Sources: Always opt for suppliers that provide sustainably sourced and eco-friendly materials. This plays a crucial role in the overall sustainability of your products.

2. Optimize Production Processes: Streamline operations to minimize waste. Techniques such as just-in-time manufacturing can help reduce excess inventory and decrease the environmental impact.

3. Implement Recycling Programs: Develop a protocol for recycling old PCBs and electronic waste. Creating a closed-loop system not only demonstrates corporate responsibility but also contributes to resource conservation.

Advancements in Multi-layer PCB Designs for Complex Applications

The advancement of multi-layer PCB designs is rapidly transforming the landscape of electronics manufacturing, primarily driven by the increasing complexity of applications across diverse industries. According to a recent report by the IPC (Institute for PCB Design and Manufacturing), the demand for multi-layer printed circuit boards is projected to grow at a compound annual growth rate (CAGR) of 9% through 2025, fueled by innovations in sectors such as telecommunications, automotive, and medical devices. These boards, typically featuring four to twelve layers or more, enable higher circuit density and improved performance characteristics, which are essential for meeting the sophisticated requirements of modern electronics.

In particular, the integration of advanced materials and manufacturing techniques is enhancing multi-layer PCB capabilities. The use of materials such as high-frequency laminates and embedded passive components is becoming increasingly prevalent, allowing for better thermal management and signal integrity. A survey conducted by ResearchAndMarkets reveals that 68% of PCB manufacturers are investing significantly in R&D for multi-layer technology, indicating a shift towards more intelligent and compact circuit solutions.

This trend is essential for addressing the growing need for high-performance electronics that can fit into smaller form factors while maintaining reliability and efficiency. As we move towards 2025, these advancements in multi-layer designs will likely play a pivotal role in the evolution of the electronics industry.

Related Posts

-

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics

-

2025 Top Innovations in Circuit Board Assembly: What to Expect in the Future

-

10 Best Circuit PCB Manufacturing Services That Enhance Your Electronics Design Efficiency

-

Top PCB Assembly Trends to Watch in 2025 for Electronics Manufacturers

-

What is PCB and Assembly Process Explained for Beginners

-

Ultimate Guide to PCB Design and Assembly Best Practices for Beginners