Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

How to Choose the Right Cable Harness for Your 2025 Project Needs

In the rapidly evolving realm of technology, selecting the appropriate cable harness for your 2025 project needs is critical for ensuring efficiency, safety, and performance. As John Smith, a renowned expert in the cable harness industry, states, "The right cable harness not only enhances the functionality of a project but also minimizes potential risks in connectivity." Understanding the multifaceted applications and specifications of cable harnesses can be daunting, especially with the myriad of options available on the market today.

As projects become increasingly complex, it is essential to grasp the unique requirements each application demands. The cable harness plays a fundamental role in managing and organizing electrical connections, significantly influencing the overall design and functionality of the system. It is, therefore, imperative for project managers and engineers to consider various factors—such as compatibility, durability, and ease of installation—when choosing a cable harness. By doing so, they can ensure that their projects not only meet the immediate criteria but are also equipped to adapt to future advancements in technology.

Table of Contents

[Hide]

Understanding the Basics of Cable Harnesses for Modern Projects

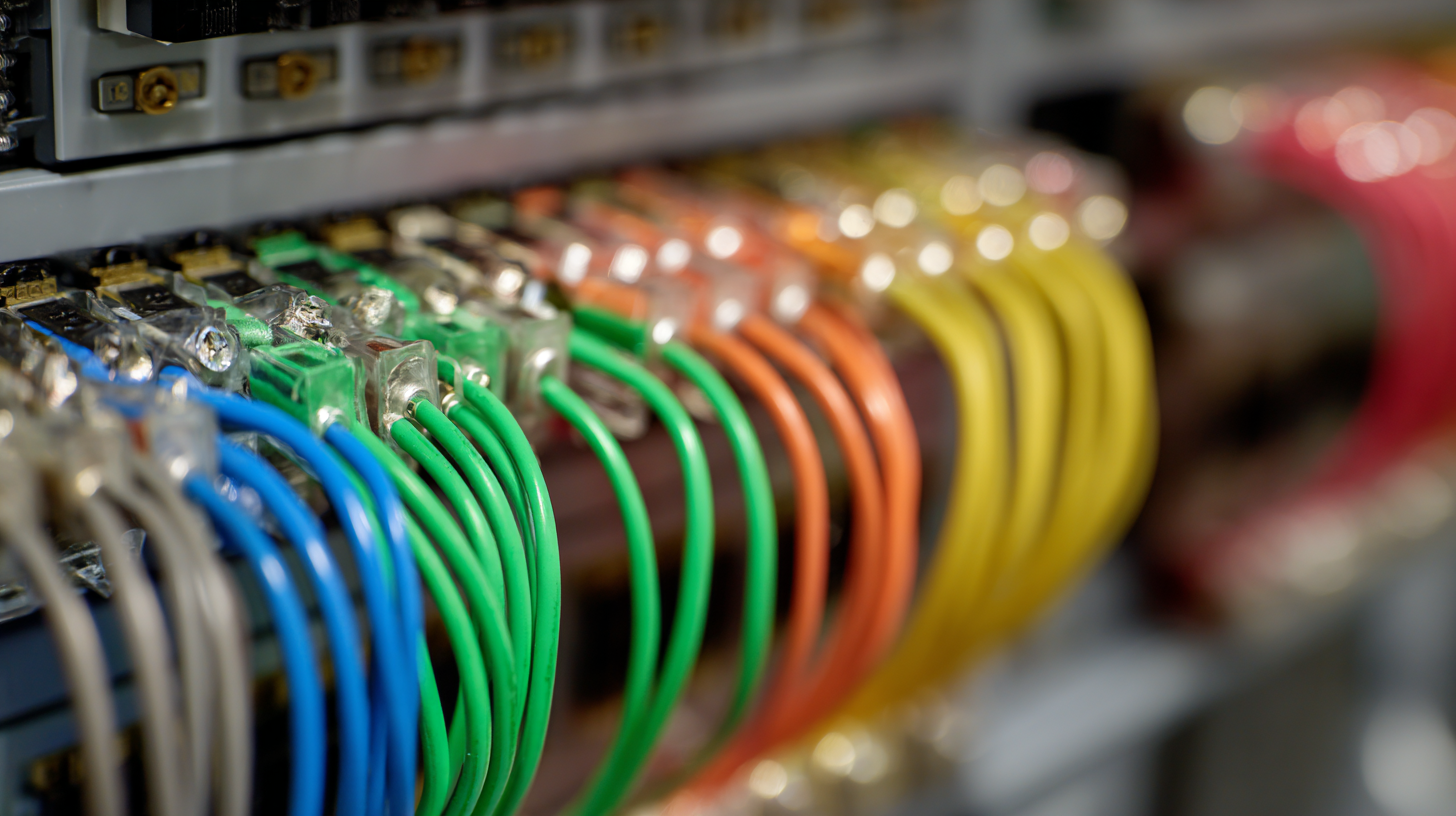

When embarking on a modern project in 2025, understanding the basics of cable harnesses is crucial for ensuring efficient design and functionality. A cable harness, essentially a bundled assembly of wires or cables, plays a vital role in connecting multiple components of electrical systems. This organization minimizes the risk of short circuits and interference, which is particularly important in today's complex electronic devices. Moreover, a well-designed cable harness can significantly reduce installation time and streamline maintenance efforts.

In selecting the right cable harness, one must consider factors like the project's specific requirements, environmental conditions, and connector types. For instance, high-temperature environments may necessitate specialized materials that can withstand extreme heat without degrading. Additionally, the choice of connectors must align with the device's function and environment to ensure reliability and ease of troubleshooting. Understanding these fundamentals will guide you in making informed decisions that enhance the overall performance and longevity of your project, setting a solid foundation for success in the fast-evolving landscape of technology.

Key Factors to Consider When Selecting a Cable Harness

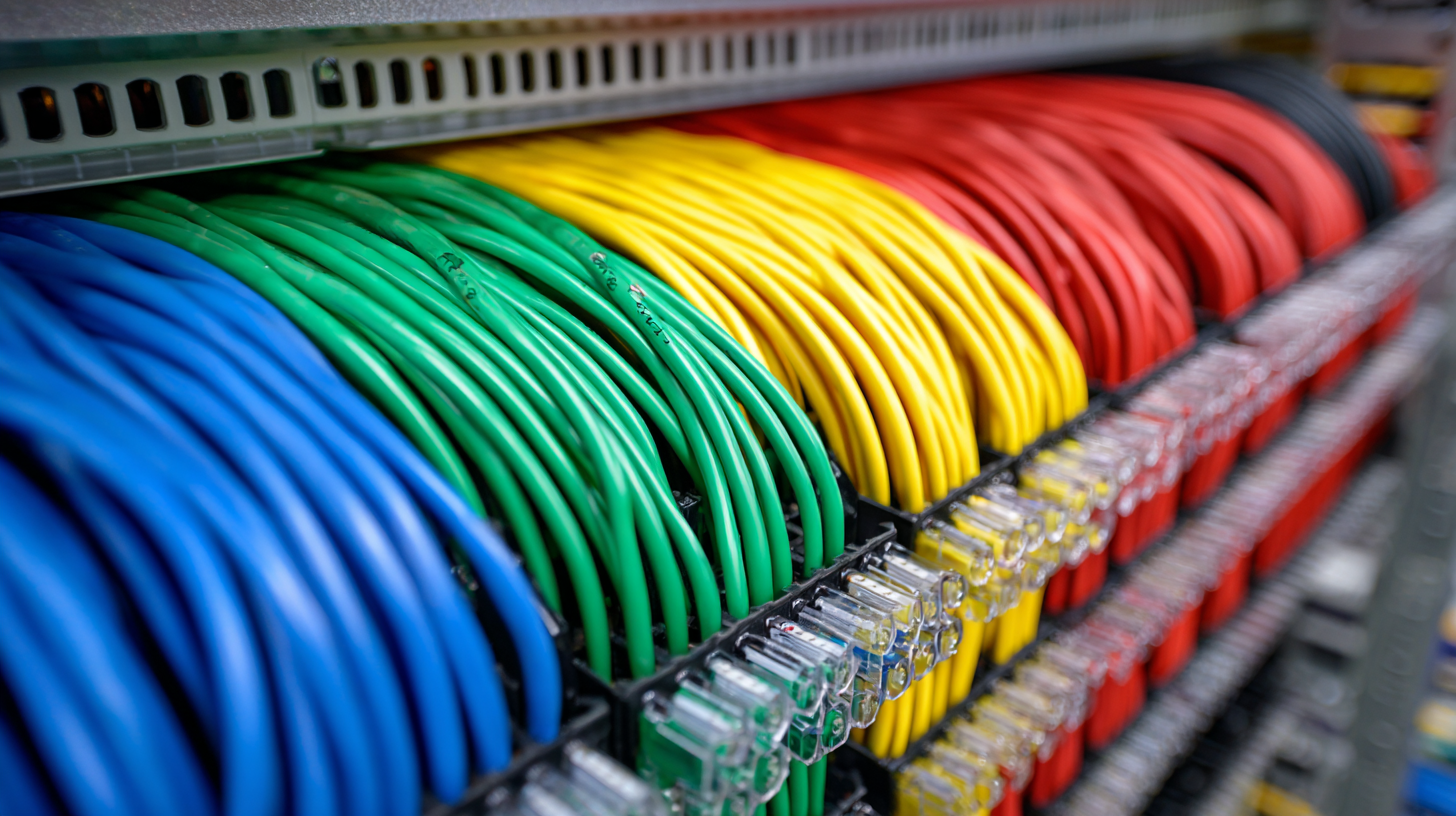

When selecting a cable harness for your 2025 project, several key factors should guide your decision-making process. First and foremost is the application environment. Consider whether the harness will be used in harsh conditions that may involve exposure to extreme temperatures, moisture, or chemicals. Understanding the environmental requirements will help determine the materials and designs that are most suitable, ensuring the harness performs reliably throughout its lifecycle.

Another critical factor is the harness's electrical specifications. You need to assess the voltage, current capacity, and data requirements of your project. This includes considering the gauge of the wire and the overall configuration of the harness to ensure it can handle the necessary load without risking failure. Additionally, it's important to think about ease of installation and maintenance. A well-designed harness should offer straightforward connectivity and routing, reducing installation time and potential for errors, which is essential for optimizing project efficiency.

Top Materials for Durable and Efficient Cable Harnesses

When selecting the right cable harness for your 2025 project needs, the choice of materials is critical to ensure both durability and efficiency. Given the expanding automotive control cable market, valued at $5.24 billion in 2023 and projected to reach $7.13 billion by 2032, the demand for robust cable harness solutions is on the rise. Therefore, understanding the top materials available on the market can significantly impact the performance and longevity of your project.

Among the most popular materials for cable harnesses are thermoplastics and elastomers, which offer excellent resistance to heat, chemicals, and abrasion. These materials help protect internal wiring from environmental factors, ensuring reliability in applications such as automotive, aerospace, and industrial sectors. Additionally, advancements in composite materials have led to lighter yet stronger harnesses, which not only enhance performance but also contribute to weight savings—a crucial factor in the automotive industry as manufacturers aim to improve fuel efficiency and reduce emissions. As such, choosing the right material for your cable harness is essential in meeting both project specifications and industry standards.

Evaluating Manufacturer Reputation and Service for Your Project

When embarking on a project that requires a custom cable harness in 2025, evaluating the reputation of manufacturers is paramount. According to a report by MarketsandMarkets, the global cable harness market is expected to grow significantly, reaching USD 80 billion by 2026, with a CAGR of over 9%. This surge underscores the necessity for businesses to partner with reliable manufacturers that not only provide high-quality products but also demonstrate robust customer service. Companies with longstanding experience and a proven track record typically exhibit greater proficiency in meeting project specifications and timelines, enabling smoother project execution.

Additionally, industry surveys indicate that 70% of respondents prioritize manufacturer support when selecting suppliers, highlighting the importance of service alongside product quality. Manufacturers who invest in responsive customer support and clear communication protocols tend to cultivate stronger relationships with their clients, ensuring that any issues during the development process are swiftly addressed. Reviews and testimonials from previous clients can serve as valuable indicators of a manufacturer’s credibility. Engaging in thorough research, including checking industry certifications and third-party reviews, will help ensure that you select a manufacturer that not only meets your project needs but also stands as a reliable partner throughout your project’s lifecycle.

Future Trends in Cable Harness Technology to Watch in 2025

As we approach 2025, the cable harness industry is poised for significant advancements driven by emerging technologies and evolving industry demands. One of the key trends is the increasing integration of smart technology within cable harnesses. This includes sensors and communication capabilities that enhance functionality and provide real-time monitoring. These innovations not only improve efficiency but also help in predictive maintenance, reducing downtime in critical applications.

Another noteworthy trend is the shift toward sustainable and eco-friendly materials in cable harness manufacturing. With growing environmental awareness, manufacturers are exploring biodegradable and recyclable options that minimize the ecological impact. This shift aligns with global sustainability goals and reflects consumer preferences for greener products. As these trends continue to evolve, understanding their implications will be essential for businesses to remain competitive and meet the changing needs of their projects in 2025 and beyond.

How to Choose the Right Cable Harness for Your 2025 Project Needs - Future Trends in Cable Harness Technology to Watch in 2025

| Aspect | Current Trends | Future Outlook (2025) |

|---|---|---|

| Material Innovation | Use of lightweight and high-durability materials. | Growth in usage of bio-based and recyclable materials. |

| Customization | Increased demand for tailored harness solutions. | More advanced configurators for rapid design processes. |

| Connectivity | Focus on high-speed data transmission standards. | Emergence of smarter harnesses with integrated IoT capabilities. |

| Production Techniques | Shift towards automation and precision in manufacturing. | Increased implementation of AI-driven manufacturing systems. |

| Sustainability | Initial steps taken to reduce environmental footprint. | Established industry standards for sustainable harness production. |

| Market Demand | Growing sectors include automotive and renewable energy. | Expansion into aerospace and robotics industries. |

Related Posts

-

Unlocking the Future: How Cable Assemblies Power Modern Technology and Innovation

-

Innovative Board Design Techniques for Enhancing User Engagement in Digital Platforms

-

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics

-

Maximizing Efficiency in PCB Assembly Through Advanced Automation Techniques for 2024

-

2025 Top Innovations in Circuit Board Assembly: What to Expect in the Future

-

Understanding Cable and Wire: A Comprehensive Guide to Their Types and Uses