Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

How to Harness Assembly for Maximum Efficiency in 2026?

In 2026, industries face increased pressure for efficiency. Utilizing innovative strategies becomes essential. One such strategy is to harness assembly effectively. This process involves optimizing workflows and reducing waste.

Harness assembly can lead to significant improvements. By focusing on collaboration, teams can streamline operations. Implementing new technologies also plays a vital role. However, challenges arise when integrating these methods. Not all ideas will fit every situation, and adapting is necessary.

Reflecting on past experiences can guide future efforts. What worked before may not work now. Continuous learning and adaptation are crucial for success. Embracing trial and error allows organizations to refine their approaches. The journey to harness assembly requires commitment and a willingness to evolve.

Table of Contents

[Hide]

Understanding Assembly: The Basics and Its Importance in 2026

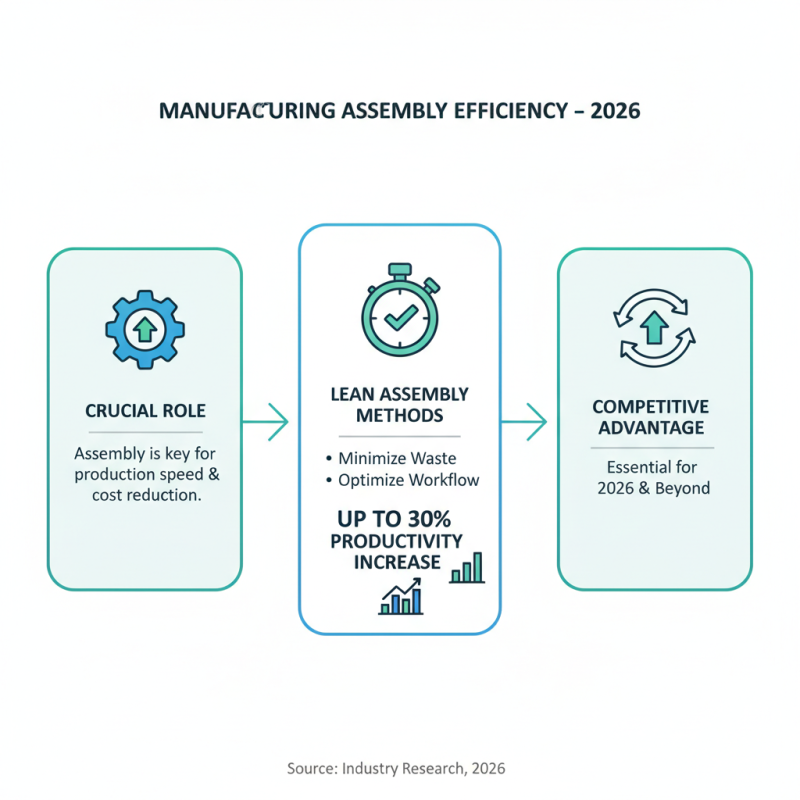

Assembly plays a crucial role in manufacturing efficiency, especially in 2026. Efficient assembly practices can significantly enhance production speed and reduce costs. Research indicates that companies focusing on lean assembly methods can see productivity increases of up to 30%. These methods emphasize minimizing waste and optimizing workflow, crucial in today’s competitive landscape.

Understanding the essentials of assembly is vital. For instance, the use of advanced technologies like automation has transformed traditional assembly lines. Reports suggest that over 60% of manufacturers plan to integrate robotics by 2026. However, implementing such technologies isn’t without challenges. Training workers to operate these advanced systems is essential but often neglected. This oversight can lead to reduced efficiency, negating the benefits of automation.

Moreover, the importance of a well-organized assembly layout cannot be overstated. A disorganized approach can lead to longer cycle times and worker frustration. Industry studies indicate that inefficient layouts can result in up to 25% more time spent on assembly tasks. Companies frequently overlook the human element in assembly. Worker engagement and feedback should shape the assembly process. Without this, even the best strategies can falter.

Key Strategies for Maximizing Efficiency in Assembly Workflows

In 2026, assembly workflows will require innovative strategies to achieve maximum efficiency. One of the key strategies involves optimizing workspaces. A cluttered environment can lead to wasted time and confusion. Organizing tools and materials has a direct impact on productivity. Simple visual cues can aid workers in quickly locating items. The layout should facilitate easy movement between workstations.

Another essential aspect is worker training. A skilled workforce enhances efficiency. Employers should invest in regular training. However, even the best training may fall short if workers do not feel motivated. Recognizing individual contributions can boost morale. Frequent feedback sessions can help identify areas for improvement. It's crucial to create an environment that encourages open communication.

Embracing technology is vital but can be challenging. Automation can streamline many processes. However, reliance on technology might lead to vulnerabilities. If equipment fails, it can halt production. Balancing manual labor and automation is an ongoing challenge. Organizations must assess their efficiency continually. Adaptability is a key factor in overcoming obstacles. Finding the right mix is not always straightforward.

Implementing Advanced Technologies to Enhance Assembly Processes

In 2026, the push for efficiency in assembly processes will rely heavily on advanced technologies. Robotics, AI, and IoT are becoming essential tools. According to industry reports, companies that implement AI in assembly see a 30% increase in productivity. These technologies help reduce human error and streamline operations. Yet, the integration process can be complex, often facing resistance from workers.

Another significant aspect is the adaptability of these technologies. The right systems can adjust to various tasks. However, reports suggest that only 29% of assembly lines are currently equipped with IoT technology. This creates a gap that companies need to address. Human oversight remains vital, as technology does not eliminate the need for skilled workers.

Training and technology must go hand in hand. Many employees feel left behind as new systems are introduced. Embracing a culture of continuous learning is crucial. The journey might be challenging, but it's necessary for long-term sustainability. Balancing innovation with employee development can lead to a truly efficient assembly process.

How to Harness Assembly for Maximum Efficiency in 2026? - Implementing Advanced Technologies to Enhance Assembly Processes

| Technology | Description | Expected Impact | Implementation Timeline |

|---|---|---|---|

| Artificial Intelligence | Using AI for predictive maintenance and quality control. | Increase efficiency by 20%, reduce downtime. | 2025-2026 |

| Robotic Process Automation | Automating repetitive tasks in assembly lines. | Reduce labor costs by 30%, improve speed. | 2024-2025 |

| Internet of Things (IoT) | Implementing smart sensors to monitor equipment. | Enhance visibility in operations, reduce waste. | 2025 |

| Augmented Reality (AR) | Training assembly workers using AR tools. | Increase training efficiency by 50%. | 2024 |

| 3D Printing | On-demand parts manufacturing to reduce inventory. | Stock reduction by 40%, faster prototyping. | 2026 |

Training and Development Approaches for Assembly Teams in 2026

In 2026, training assembly teams requires innovative approaches. Effective training methods must integrate hands-on experiences with theoretical knowledge. Workshops that simulate real-world scenarios can enhance understanding. Teams should engage in problem-solving exercises that mirror daily challenges. These methods build critical thinking skills and foster collaboration.

Mentorship programs are another valuable approach. Pairing experienced workers with newcomers encourages knowledge transfer. This relationship offers immediate feedback and personalized guidance. However, there can be a disconnect if mentors lack engagement. Mentors need to be aware of their communication style and its impact.

Assessment of training effectiveness should be ongoing. Regular feedback loops are essential. Gathering insights from team members helps identify areas for improvement. It’s important to recognize not all strategies will succeed. Training should evolve based on team input and shifting demands in assembly processes. Each reflection can pave the way for a more effective training approach.

Measuring and Analyzing Assembly Performance for Continuous Improvement

Measuring assembly performance is crucial for continuous improvement. Organizations can use various metrics to analyze how efficiently assembly tasks are completed. For instance, tracking the time taken for each assembly process can reveal bottlenecks. Identifying these slow points allows teams to focus their improvement efforts effectively. Regular assessments can then measure progress over time.

In addition to time, accuracy should also be monitored. Errors in assembly lead to increased costs and delays. By examining error rates, teams can pinpoint recurring issues. However, some teams overlook these details, believing they can manage without them. Such oversights can impede overall efficiency. Creating a culture of accountability encourages individuals to take responsibility for their work.

Feedback loops are essential in this process. Gathering input from assembly workers provides invaluable insights. These individuals often have unique perspectives on challenges faced daily. However, organizations sometimes neglect their voices. This disconnect can hinder innovation and improvements. Emphasizing open communication creates a more supportive environment for everyone involved.

Assembly Performance Metrics - 2026

Related Posts

-

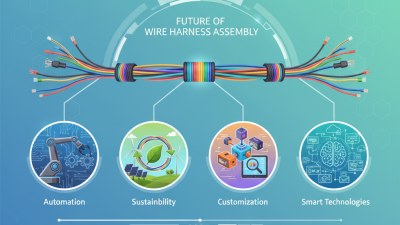

Top Trends in Wire Harness Assembly for 2025: What You Need to Know

-

Top 10 Best Tips for Electronic Board Design Success?

-

Understanding Cable and Wire: A Comprehensive Guide to Their Types and Uses

-

Top 10 Tips for Effective Circuit Board Design Strategies?

-

Unlocking the Future: How Cable Assemblies Power Modern Technology and Innovation

-

Top 10 Benefits of Circuit Board Assembly for Modern Electronics?