Let Us Know How We Can Help. We Are Your Dedicated Solutions Provider.

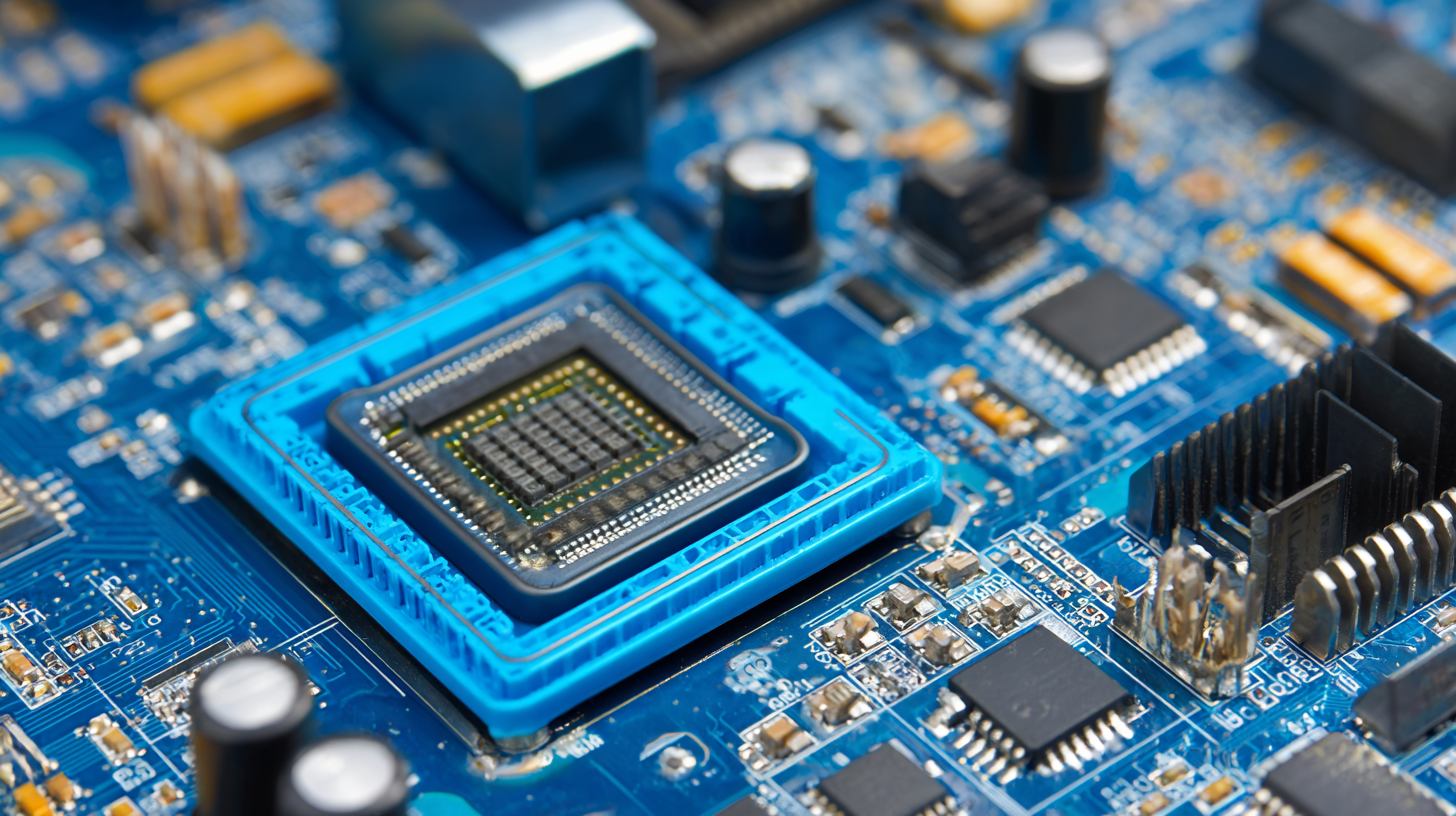

Why Printed Board Assembly is Essential for Modern Electronics Manufacturing

In the rapidly evolving landscape of electronics manufacturing, printed board assembly (PBA) stands as a cornerstone of innovation and efficiency. As the demand for smarter, faster, and more reliable electronic devices soars, the significance of PBA in the manufacturing process cannot be overstated. According to a recent report by the IPC (Association Connecting Electronics Industries), the global printed circuit board (PCB) market is projected to reach $85 billion by 2024, underscoring the essential role that PBA plays in meeting the needs of this booming industry.

The shift towards miniaturization and increasing complexity of electronic components has rendered traditional manufacturing methods obsolete. With advancements in technology, modern PBA techniques leverage automated assembly processes that enhance precision, reduce production time, and minimize costs. Research by Deloitte indicates that companies adopting advanced PBA methodologies can achieve up to a 30% reduction in operational expenses while simultaneously increasing production output. This alignment between technological capabilities and market demand highlights why printed board assembly has become an essential element for electronics manufacturers looking to gain a competitive edge in a dynamic marketplace.

As we navigate toward 2025, understanding the critical role of printed board assembly in the life cycle of electronic products will become increasingly vital. The integration of PBA in the manufacturing process not only ensures quality and performance but also aligns with sustainability initiatives aimed at reducing waste in electronics manufacturing. Thus, it is imperative for industry stakeholders to recognize and invest in PBA technologies to thrive in an ever-competitive environment.

Table of Contents

[Hide]

The Critical Role of Printed Board Assembly in Electronics Production

Printed Board Assembly (PBA) plays a critical role in electronics production, serving as the backbone for modern electronic devices. According to a report by MarketsandMarkets, the global market for Printed Circuit Boards (PCBs) is projected to reach a staggering $82 billion by 2024, driven by the increasing demand for consumer electronics, automotive applications, and telecommunications. This aligns with the trend of miniaturization and the need for more complex circuit designs, which rely heavily on PBA for efficiency and performance.

Furthermore, a survey conducted by IPC shows that approximately 70% of electronics manufacturers consider PBA to be the most significant factor influencing the reliability and performance of their products. As devices become more intricate, the precision and quality of PBA processes, such as soldering and component placement, are crucial. Advanced techniques, including surface mount technology (SMT) and automated assembly processes, are continuously evolving to enhance production efficiency and reduce costs, further underlining PBA’s importance in the competitive landscape of electronics manufacturing.

Advancements in PCB Technology Shaping Modern Manufacturing Trends

The electronics industry is undergoing a significant transformation, with advancements in printed circuit board (PCB) technology playing a crucial role in this evolution. As manufacturers seek to enhance efficiency and reliability, the miniaturization of PCBs has become a core focus. This trend is not only facilitating the development of compact devices but also bolstering performance metrics across various sectors. For instance, the global automated optical inspection (AOI) system market is projected to reach a staggering USD 849.5 million by 2024, emphasizing the industry’s dedication to advanced quality control and precision in PCB assembly.

The electronics industry is undergoing a significant transformation, with advancements in printed circuit board (PCB) technology playing a crucial role in this evolution. As manufacturers seek to enhance efficiency and reliability, the miniaturization of PCBs has become a core focus. This trend is not only facilitating the development of compact devices but also bolstering performance metrics across various sectors. For instance, the global automated optical inspection (AOI) system market is projected to reach a staggering USD 849.5 million by 2024, emphasizing the industry’s dedication to advanced quality control and precision in PCB assembly.

Moreover, the printed circuit board assembly market is set to witness substantial growth, expected to reach USD 161.6 billion by 2035, with an impressive CAGR of 5.0%. This growth is primarily driven by the increasing demand for more sophisticated electronic applications, especially within the electric vehicle market. The substrate-like PCB segment is particularly noteworthy, as it is forecasted to achieve a remarkable 19.5% CAGR, with an estimated market size of USD 8.9 billion by 2034.

Tip 1: To keep pace with these technological advancements, manufacturers should invest in automated solutions to optimize their production processes and ensure high-quality outputs.

Tip 2: Staying informed about industry trends through platforms like Productronica 2025 can provide valuable insights and networking opportunities that could benefit your manufacturing strategies.

Key Benefits of Efficient PCB Assembly in Reducing Production Costs

Efficient PCB assembly plays a crucial role in modern electronics manufacturing by significantly reducing production costs. As the demand for high-performance electronic devices continues to rise, manufacturers are seeking ways to optimize their processes. Printed Board Assembly (PBA) offers several key benefits that lead to considerable cost savings, including reduced material waste and lowered labor expenses. By streamlining assembly processes and utilizing advanced automation technologies, companies can enhance their production efficiency while maintaining quality standards.

In the rapidly evolving landscape of electronics, technologies such as CoWoS packaging have emerged to meet the increasing demands for enhanced computational power driven by AI applications. While this innovative approach gains traction, efficient PCB assembly remains a foundational aspect of electronic manufacturing. The scalability of PBA allows it to adapt to emerging technologies and market shifts, ensuring manufacturers can meet consumer needs without compromising on cost-effectiveness. Ultimately, the integration of efficient PCB assembly techniques is essential for businesses to stay competitive and responsive in the face of growing industry challenges.

Innovations in Printed Circuit Boards for Enhanced Performance and Reliability

Innovations in printed circuit board (PCB) technology are pivotal in enhancing the performance and reliability of modern electronics. With the global PCB market expected to reach $87 billion by 2026, the demand for high-density interconnect (HDI) boards and flexible PCBs is skyrocketing. These advancements enable manufacturers to produce smaller, lighter, and more complex devices that cater to the growing needs of sectors like telecommunications, automotive, and consumer electronics. For instance, HDI PCBs can increase the routing density by up to 50%, which significantly optimizes the compactness of electronic devices.

The integration of advanced materials, such as high-frequency laminates and thermally conductive substrates, further boosts PCB reliability under extreme conditions. According to a report by IPC, the market for materials used in PCBs is projected to grow at a CAGR of over 5% through 2024. This growth reflects a push towards greater thermal and electrical performance, essential for applications in 5G technology and electric vehicles. With innovations in manufacturing processes, like automated optical inspection and advanced soldering techniques, manufacturers can ensure superior quality control, ultimately leading to improved lifespan and reliability of electronic products.

The Future of PCB Assembly: Trends and Predictions for 2025

The future of PCB assembly is poised for significant transformation by 2025, driven by advancements in technology and the increasing demand for miniaturization in electronic devices. According to a report from Research and Markets, the global PCB market is expected to reach $85 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.4% from 2020. This growth is largely attributed to the rising prevalence of smart devices and the Internet of Things (IoT), which require highly efficient and compact printed circuit boards.

Additionally, the shift towards more sustainable manufacturing practices is influencing trends in PCB assembly. A study by the IPC (Association Connecting Electronics Industries) highlights that companies are increasingly adopting eco-friendly materials and processes. The demand for using lead-free solder and recyclable substrates is expected to rise significantly, with projections indicating that more than 70% of PCB manufacturers will implement green practices by 2025. As a result, the industry is not only aligning with regulatory requirements but is also responding to consumer preferences for environmentally responsible products, which will ultimately shape the future landscape of PCB assembly in the electronics sector.

PCB Assembly Trends and Predictions for 2025

Related Posts

-

Understanding the Future of Electronic Board Assembly in Modern Technology

-

Maximizing Efficiency in PCB Assembly Through Advanced Automation Techniques for 2024

-

2025 Top Innovations in Circuit Board Assembly: What to Expect in the Future

-

Innovative Board Design Techniques for Enhancing User Engagement in Digital Platforms

-

Exploring the Evolution of PCB Fabrication: From Concept to Reality in Modern Electronics

-

How to Choose the Right Cable Harness for Your 2025 Project Needs